How Unified Communications Keeps Manufacturing Teams Efficient, Safe, and Online

In manufacturing, clear and timely communication keeps everything moving. When messages don’t reach the right people fast enough, things start to break down—machines sit idle, deliveries get pushed back, and safety takes a hit. Teams end up working in silos, reacting instead of staying ahead. And the longer it takes to connect, the more it costs.

Studies estimate that downtime can cost manufacturers anywhere from $5,600 to $22,000 per minute, depending on the industry. And while automation and IoT get all the buzz, many factories still struggle with basic communication breakdowns—from outdated radios to patchwork tools that don’t talk to each other.

Unified Communications (UC) can change that. But before we get into the solution, let’s dig into the real problems manufacturers are facing today.

Communication Blockers in Manufacturing

Downtime Disrupts Everything

A line operator notices a defect forming on the line. He radios the floor supervisor. No response. He tries calling, but the supervisor left the desk phone for a meeting on the other side of the plant. By the time the issue is flagged, hundreds of faulty products are already boxed and on their way out the door.

That’s not a freak event; it’s routine in environments where communication is disjointed. Whether it’s a delay in getting maintenance to the floor or a logistics team unaware of a hold-up upstream, miscommunication turns into missed quotas, wasted materials, and angry customers.

Safety Risks from Delayed Alerts

A spill goes unnoticed. A machine overheats. A worker forgets to log a lockout. All it takes is a moment and a delay in communication to turn a near miss into a serious incident.

For environments filled with heavy machinery, chemicals, and fast-moving parts, every second counts. If alerts don’t reach the right team in real time, safety compliance becomes a guessing game, and the human cost can be devastating.

Scattered Tools Waste Time

A lot of manufacturing teams juggle radios, emails, mobile apps, and desk phones just to stay in touch. But when something goes wrong, jumping between all those tools slows everything down. In high-stakes situations, that delay can put people at risk.

The production team uses walkie-talkies. The warehouse relies on text chains. Maintenance logs are sent via email. Meanwhile, the plant manager tries to make decisions with half the picture. The result? Slower responses, mixed signals, and a whole lot of wasted time.

How Unified Communications Addresses These Challenges

A unified communications solution consolidates all communication into a single, integrated platform, built for the speed and complexity of modern manufacturing.

Integrated Communication Platforms

You’re mid-chat when things escalate—so you switch to video on your phone, then tap once to bring in the maintenance team. No app-hopping, no friction. Just one system, zero headaches.

With a unified communications system in place, departments stay connected and synchronized. Everyone sees the same messages, the same alerts, the same status updates. No more guessing who knows what.

Reliable Connectivity with Failover Options

Internet outage during a shift change? UC systems with built-in 4G/5G failover keep critical lines of communication online. When Wi-Fi goes down, operations don’t have to.

This level of redundancy is crucial in manufacturing environments where every minute of silence equals lost revenue.

Real-Time Alerts and Notifications

Custom alerts keep your team ahead of risks, whether it’s a QA hiccup or a safety emergency. Trigger a plant-wide evacuation or ping only the forklift crew in seconds. No guesswork, no delays. Because when seconds count, your alerts shouldn’t just inform, they should act. Stop accidents before they happen and cut downtime before it starts.

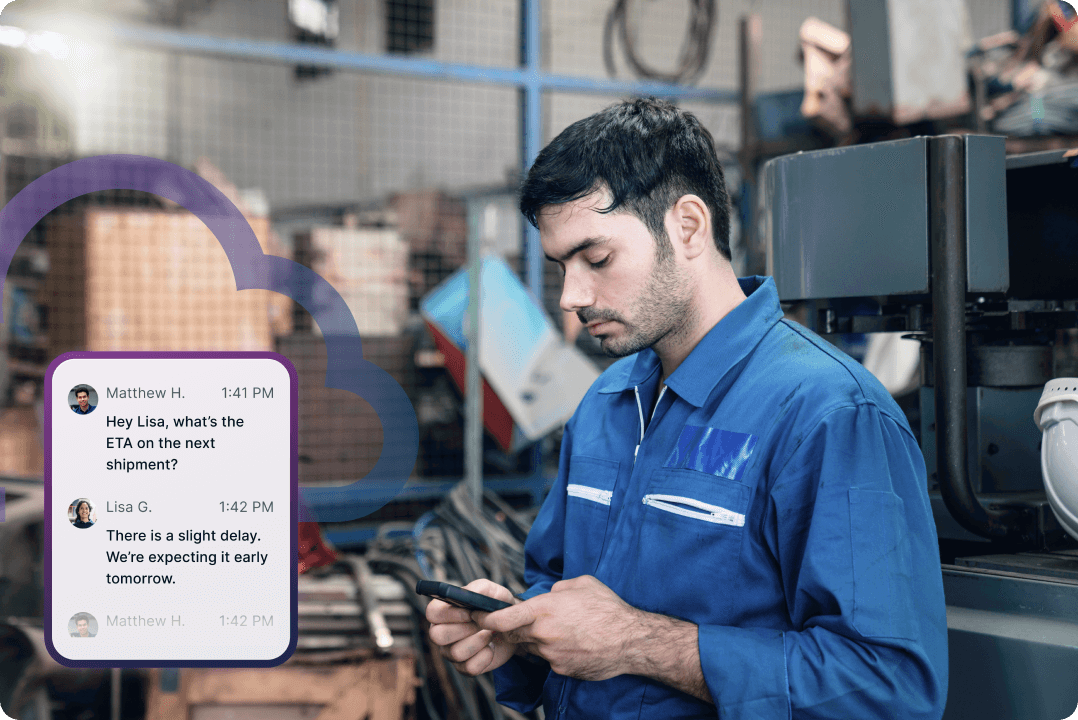

Mobile Accessibility for On-the-Go Teams

Supervisors, field technicians, and warehouse leads are rarely at a desk. UC apps for iOS and Android let them stay connected without missing a beat—whether they’re on the floor, on a forklift, or offsite.

With presence indicators and synced communications, teams know exactly who’s available and who’s already on a task.

Deployment Options Tailored to Manufacturing Needs

Manufacturers aren’t one-size-fits-all, and neither is UC. Sangoma offers flexible deployment models to fit every environment.

Cloud UCaaS for Flexibility

Unified Communications as a Service (UCaaS) delivers the entire system via the cloud. It is perfect for manufacturers who want scalability without managing infrastructure.

Cloud UCaaS is ideal for multi-site operations or manufacturers expanding rapidly. Updates roll out automatically, and centralized management means your team doesn’t need to chase issues across multiple sites. If you’re working across borders or running lean on IT, this is the model built for you.

Hybrid UC for Balanced Control

Some plants need the flexibility of cloud, but also want on-site survivability in case of internet issues or compliance concerns.

A hybrid UC model blends both worlds: cloud-based features plus local infrastructure for critical systems. It’s the best of both, especially for plants with strict uptime or security needs. It’s a strong fit for plants with compliance requirements, legacy hardware, or safety protocols that demand always-on internal comms. The hybrid unified communications model also supports multi-location setups with local failover, so even if your connection drops, critical systems keep working.

On-Premises UC for Maximum Control

For manufacturers with deep investments in existing infrastructure, or strict regulatory requirements, an on-premises unified communications setup provides total control over data, security, and customization.

Compared to cloud or hybrid setups, an on-prem deployment can reduce long-term costs by reusing existing desk phones and infrastructure. It also allows for precise call handling via features like queue management, presence monitoring, and a built-in switchboard interface.

With Sangoma’s on-prem UC—powered by Switchvox—you get a fully featured VoIP phone system with advanced features like call routing, paging, voicemail-to-email, and integration with tools like Microsoft Teams. The system runs locally, meaning your communications continue uninterrupted even during internet outages.

This deployment model works best for facilities with an in-house IT team and high standards for system oversight.

How Unified Communications Improves the Workday

UC isn’t just a backend improvement—it reshapes the daily experience for people across the factory floor.

Production Stays on Schedule

When shift leads can reach maintenance in seconds, or logistics teams can coordinate with QA instantly, the line keeps moving. UC reduces guesswork and delays, streamlining everything from raw materials to outbound shipping.

With clear communication trails, you know who made a call, when, and why, making it easier to escalate issues and make fast decisions.

Improved Safety Compliance

Real-time alerts help catch issues before they escalate. Instead of relying on manual check-ins or radio messages, safety protocols are digitized and instantly distributed.

Manufacturers using real-time alert systems experience 47% faster incident response times and 28% fewer safety-related stoppages, according to a Deloitte analysis of Industry 4.0 implementations.

Less IT Overhead

With fewer tools to manage and a centralized system, UC reduces the burden on IT teams. No more patching together radios, email servers, and separate apps.

AI-driven features like voicemail-to-text, intelligent routing, and auto-escalations free up even more time, letting your IT team focus on high-impact tasks.

What Sangoma UC Brings to the Floor

Sangoma’s Unified Communications system is built for manufacturing realities—not (just) office cubicles. It provides rugged reliability, intuitive tools, and features designed for speed and safety.

Built to Support Production

Our UC platform will become the backbone of your factory floor. Every feature is engineered to keep your team moving: decisions faster, workflows safer, and operations uninterrupted.

Voice, video, chat, and SMS all live in one place, so your crew can focus on the job, not the software. TeamHub integration ties departments together with shared conversations and task-focused threads, eliminating silos before they slow you down.

Need to rally the forklift team or flag a QA issue? Push-to-talk and real-time alerts cut through the noise with hands-free updates. With full mobile access on iOS and Android, supervisors and remote techs stay plugged in, whether they’re on the line or across the facility.

Trusted by Manufacturers Worldwide

With 99.999% uptime, Sangoma UC and UCaaS is built for environments where every second of stoppage costs money.

It plays nice with the tools you already rely on, from Microsoft Teams to Salesforce and major CRMs, and fits into your existing infrastructure. But what sets it apart is the support: 24/7 expert support means you’re never left troubleshooting alone.

From Fortune 500 plants to specialized suppliers, manufacturers worldwide bet on Sangoma because it keeps up and running.

Ready to unify your plant’s communications?

Talk to our team today and find out how Sangoma can help your operation stay efficient, safe, and always online.